Challenges of Road Transport in 2024 (part 2)

- Thorsten Runge

- Feb 13, 2024

- 6 min read

In 2024, and beyond, road transportation faces a number of complex challenges. Transportation and logistics companies will need to adapt, to innovate and be proactive to ensure long term viability.

Much has been written about these numerous challenges already so, in this blog I’ll focus more on potential solutions rather than going over old ground.

The challenges addressed here are also not an exclusive list. There are many more, but I would like to concentrate on those that are addressable not only for the major players in the industry.

Part 1 deals with fuel price fluctuations and the transition to cleaner vehicles.

Here, in part 2, I am looking at

Digitalisation and route optimisation

Managing driver shortage

Digitalisation and Route Optimisation

Digitalisation or Digital Transformation is probably one of the most misunderstood terms of our time. I have met with more than just a few companies that believed business transformation can be achieved only by (more) digitalisation.

Wrong!

A new software or new hardware on its own will transform almost nothing.

A common definition of digitalisation is: “The use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business.” and the key words here are “use…to change”. It doesn’t say “digital will change a business model”. Changing the business model and/or figuring out what new revenue streams can be exploited is down to the people managing the business.

The bad news here is that you can’t just buy a new business model off the shelf.

The good news is that you may not have to invest in expensive new technology and can just use what you have more efficiently or in a different way.

A real life example to show that this can work:

A large transportation company needed to maximise the revenue per transportation unit (trailer, train, ship). Freight units (pallets, containers, etc.) were almost always in over supply so, in theory, it would be possible to determine the best mix of freight units to maximise the revenue per loaded transport unit. Their operating system was quite dated though and whilst a revenue report could be generated after the departure of a transport unit there was no visibility of the revenue opportunities real time because the relevant data could not be extracted from the system. At least not for the people making the decisions what to load and not to load on the day. The IT team told me that a new operating system would be needed to get the data real time but that would have required major investment and, even if funding was available, migration to a new operating system would take about a year at best. So, I hired someone who, I knew, could get to any data in any system.

We managed to extract the information and fed it a newly designed Power BI dashboard that could be easily accessed by the people making the loading decisions. All this took about 3 weeks, it required almost no investment and the positive impact on revenues was significant. The digital bit, albeit aged, was already there. We just used it in a new way.

We wend from human experience based decision making to to data driven decision making.

We digitalised!

[1] credit: forbytes.com

Even if financial resources were abundant and if time was not a constraint I would recommend not to jump to “tech buying mode” right away because, quite often, it is not known what exactly to buy. One way to address this is to manually mimic what you think a new system would have to automate (At Amazon we did this actually quite often. We would employ a team of students manually processing excel spreadsheets in the way we imagined a new system to work and then analyse the outcome. Only once we were satisfied we would actually build the software). The benefit is that, if you get it wrong first time, you can change things around as many times as you like without a major cost impact. At the end you will know exactly what you need and what the positive impact will be.

Then you buy.

Where to start digitalizing then?

Until recently the Chartered Institute of Logistics & Transport UK had broken down the transport / logistics journey into 7 R’s.

Right product, in the Right quantity, in the Right condition, at the Right place, at the Right Time, to the Right Customer, at the Right price but there is an 8th R that that is crucial: The Right Customer Experience. (Amazon realised this already decades ago: “Start with the customer and work backwards”.)

[2] credit graphic: Chartered Institute of Logistics & Transport UK

The digital journey in transportation and logistics is not that of a freight unit; it is the journey of the customer.

Whatever change is made to processes or the business model, whatever automation is introduced; it must benefit the customer.

LEAN 6s can help defining good processes that then can be automated but going into detail here would go far beyond the topics covered in this blog.

Operational efficiency remains critical in 2024 and, most likely, Route Optimisation will be part of the digitalisation process of the business.

There is an abundance of Transportation Management Systems (TMS) available, and AI plays a key role here.

I will not go into a comparison of various TMSs here but there are 3 important factors that should be considered when choosing a TMS:

First and foremost: Don’t let anyone tell you that you need to change all your processes to “accommodate” the TMS. It should be the other way around. Good software makes good! processes more efficient, it reduces defects and it make the processes faster; it will not design processes for a business.

Future proof the TMS. E.g. if the use of EV trucks is anticipated then it needs to factor in when and where to charge cost effectively without adding mileage and without wasting valuable drivers’ working hours. Not all TMSs on the market today are capable of mastering this.

The TMS provider should develop and update functionality continuously. Once-a-year type batch updates can be costly, and the time lag can hamper innovation in the user’s business.

Last, but not least, a TMS can help to alleviate driver shortage but more about that below.

Managing driver shortage.

Don’t expect any rocket science or a silver bullet here please.

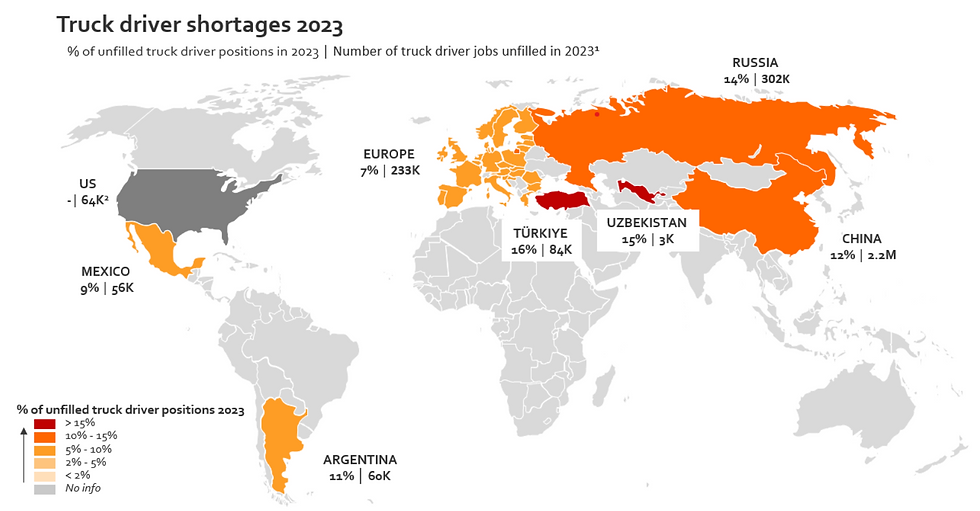

The shortage of qualified drivers is not a new challenge, and it will stay with us in 2024 and beyond. It will get worse actually as many drivers are reaching retirement age whilst few young ones are joining the ranks. According to the IRU [3] the average age of a truck driver in Europe is 47 and 34% of the drivers are older than 55. That means 34% of EU drivers will retire within the next decade or so. A massive gap between the number of new starters and retirees!

[3] IRU: Global driver shortages: 2023 year in review. Dec. 2023

The European Commission’s proposal to reduce the minimum age (so far only for bus drivers) to 18 is not going to help in 2024 and, at least for small / medium sized transportation companies, to hire drivers from non-EU countries like Uzbekistan, Tajikistan, Kyrgyzstan, or Kazakhstan may not be realistic in the short term.

[4] IRU: Global driver shortages: 2023

So, what can be done now by the individual business?

A number of transport businesses already post driver jobs on social media (rather than only on the usual job portals) which allows push notifications rather than waiting for a jobseeker logging into a job portal. Social media also works better on mobile phones rather than a web-based portal. Social media reach is also greater as almost everyone has Facebook, Instagram, etc.

The first step in the application process should be super simple, ideally 1-click. A cover letter, CV and 20 questions in the first step are likely to be “killers”.

As for driver retention, technology / TMSs can be used to help drivers find better routes, use safer roads or to minimise traffic jam situations. Good for the driver and the business.

Data from the technology can be used to structure fair and affordable bonus schemes.

Several major transportation companies have started to introduce what is still notably absent in much of the industry: a clearly defined career path!

There are no barriers for, say, a warehouse operative to become a supervisor, a shift leader and then a warehouse manager. A junior construction worker can naturally move to team leader, supervisor and site manager. The list of industries with natural career paths is long. The career path for drivers seems to be notably absent though.

The problem is compounded by the fact that driving is physically challenging. At an age of 25 weeks after week on international long-haul trips may be OK but at 55 it’s a different story. So why would one become a truck driver at a young age knowing that at 55, or so, the “career” is over?

Innovation in attracting and retaining drivers is just as important as in technology because without the driver there’s no need for the technology (well, at least as long as autonomous vehicles haven’t eliminated the problem but that’s not for 2024…)

Conclusion?

The list of challenges for road transport is a long one (no news there...) and the time to act and to innovate is now.

Acting and innovating (at least, starting to) does not require multi million investments and it does not require a massive senior management team.

Acting and innovating is for every size of business!

Comments